|

|

|

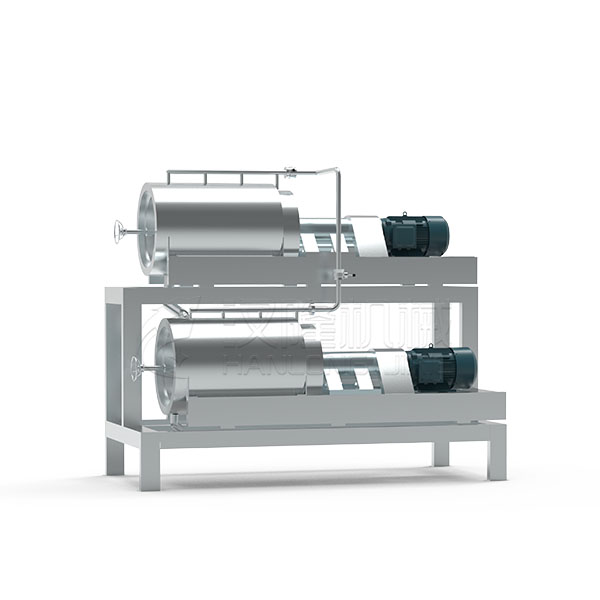

Name | Technical indexes |

|

|

|

|

|

Production capacity |

10t/h |

|

|

|

|

|

Matched power |

30kw |

|

|

|

|

|

Conveyor speed |

970r/min |

|

|

|

|

|

Overall dimensions |

1980×1200×2050mm |

|

|

High-power beater for peeling tomatoes its main working principle: Work, by the drive motor to drive the spindle rotation, when after the broken fruit of feed pump into a pulper feed mouth, make the material into the buffer chamber after diffuse into the working chamber, under the influence of main shaft and blade rotation, the cylinder to the outlet of material moving, moving trajectory spiraling, screen mesh material on the blades and the effect of the centrifugal force in the process of moving and be chopped, Juice and meat (pulp) from the sieve hole through a pulp hopper into the two beat feed port, through the two beat to refine the material. The skin and seeds are discharged from the slag hopper to achieve automatic separation. At the same time, a dilution port is arranged on the barrel body of the beater, through which the material can be diluted. It can be seen from the structure diagram that the machine has two beating, the principle of two beating is the same as a beating principle, when a beating is finished, and then sent to two beating for refinement.