I. Equipment Overview:

This equipment is a special equipment for processing fresh grapes in wineries. It can be used for grape stem separation, removal of stem branches, crushing and other processes. It is an ideal pre-processing equipment for small and medium-sized wineries. The main technical characteristic is to remove stem first and then break, with feeding screw, can realize quantitative feeding. The crushing roller is made of non-toxic high elastic rubber, which has no damage to grape kernel. The contact part and exposed part of the machine are all made of high quality stainless steel.

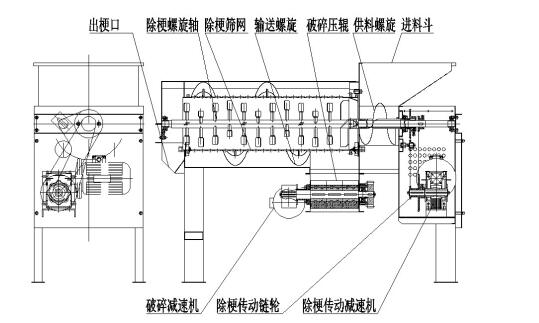

2. Schematic diagram of main structure

Three, the working principle

Grape by feeding hopper through feeding screw quantitative into the deseller screen, due to the rotation of the deseller shaft, the leaf on the shaft of the grape fruit grain and fruit stem broken apart. The stalk removal blade is mounted on the main shaft in spiral shape, and the stalk branch is discharged from the end of the sieve by high speed rotation. After the stem removal, the fruit falls into the lower crushing device from the round hole on the rotary screen, and the fruit is broken to the technological requirements by the rotating extrusion of two groups of crushing rollers. The crushed pulp falls into the single screw pump at the bottom and is transported to the next process.

V. Operation, use and precautions

1. Before installation, check whether the equipment is damaged or missing parts during transportation.

2. The equipment installation site shall be hardened and kept level. And has good drainage performance.

3, each reducer, stepless governor should be injected with lubricating oil according to the requirements of the manual, the transmission chain coated with grease, each bearing injected with appropriate lubricating oil.

4. After the installation of the equipment, check whether the fastening parts are firm and clean up the sundries in the machine. Read the instructions carefully.

5, commissioning

A. Press the button to start the deseller and turn the screen to watch from the end of the device. It should rotate counterclockwise, and the deseller rotates in the same direction with the sieve at different speeds.

B. Press the crushing start button, and a pair of gears on the crushing roll should rotate relative to each other. And the trend of discharging.

C. Ensure that all transmission parts work normally before starting the machine. No feeding empty operation for 1 hour, the equipment should not have abnormal noise, the bearing should not be too high temperature abnormal phenomenon.

6. Commissioning trial production:

A. Start the device in the following sequence:

Crushing device - stem removal device

B. Prevent iron, bricks, stones and other hard sundries from entering the machine before feeding

C. If it is found that the number of entrain fruit grains in the fruit stem outside the discharge machine increases, or the amount of ridges is reduced, check whether there are entangling objects and other faults on the stalk removing shaft.

D. If the grape is crushed directly without removing the stalk, it can be removed and the shaft can be used.

(Just remove the four M12 nuts at the end of the machine)

E. Clean the whole machine with clean water after each work, and no residue or sewage shall be left in the screen, crushing roller and slurry pump.

F. Do not troubleshoot device faults when starting the device.