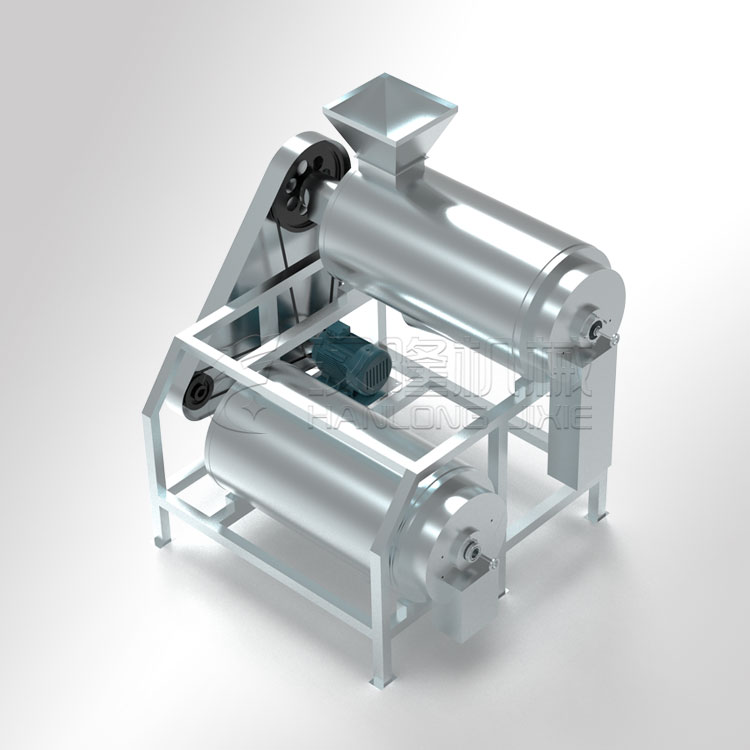

|

Model

|

Production capacityt/h

|

Matched power kw

|

Overall dimension mm

|

||||

|

MDJ1-2.5

|

1-2.5

|

4

|

1450×820×1580

|

||||

|

MDJ2-4

|

2-4

|

7.5

|

1510×1370×1700

|

||||

|

MDJ2-7.5

|

4-7.5

|

18.5

|

1930×1540×1950

|

Blueberry peeling fine beater Operation and maintenance

1. The machine must be installed horizontally and fixed with anchor screws.

2. Tighten bolts on all parts of the machine and check whether all screws in the shaft are loose. Clean the inside and outside of the machine to keep it clean.

3. Switch on the power supply of the drive motor and make sure that the rotation direction of the machine is consistent with the direction indicator.

4. Test run for 5 minutes, after confirming that everything is normal, normal feeding can be done.

5, then evenly add to the material, do not impact. According to the specific conditions of slagging and pulping, the screw Angle of the scraper and the gap between the scraper and the screen should be adjusted properly after the machine is shut down so that the juice content of the residue can meet the technological requirements. The screw Angle adjustment method of the scraper: adjust the tilt of the scraper by adjusting the bolts on the front and rear axle; The clearance adjustment method of scraper and screen: adjust the distance between the beating plate and screen by adjusting the nut on the shaft.

6, stop, directly cut off the power supply of the motor. Do not open the front cover when the rotor has not stopped rotating. Turn the hand wheel counterclockwise to open the front cover.

7. After each shift, the filter must be washed with water and a brush. When cleaning, open the front cover of the cylinder, unscrew the tension screw at one end of the spline, then the rotor parts can be easily extracted, and the screen can be taken out directly.

8. Check regularly whether the motor is overloaded and heated, and whether the bearing part is refueled.