|

Model

|

Production capacityt/h

|

Matching power kw

|

Dimensions mm

|

||||

|

CPS-2

|

2

|

3

|

950×660×1635

|

||||

|

CPS-5

|

5

|

5.5

|

1200×740×1920

|

||||

|

CPS-10

|

10

|

11

|

1300×830×2070

|

||||

| CPS-20 | 20 | 22 | 1800×980×2320 |

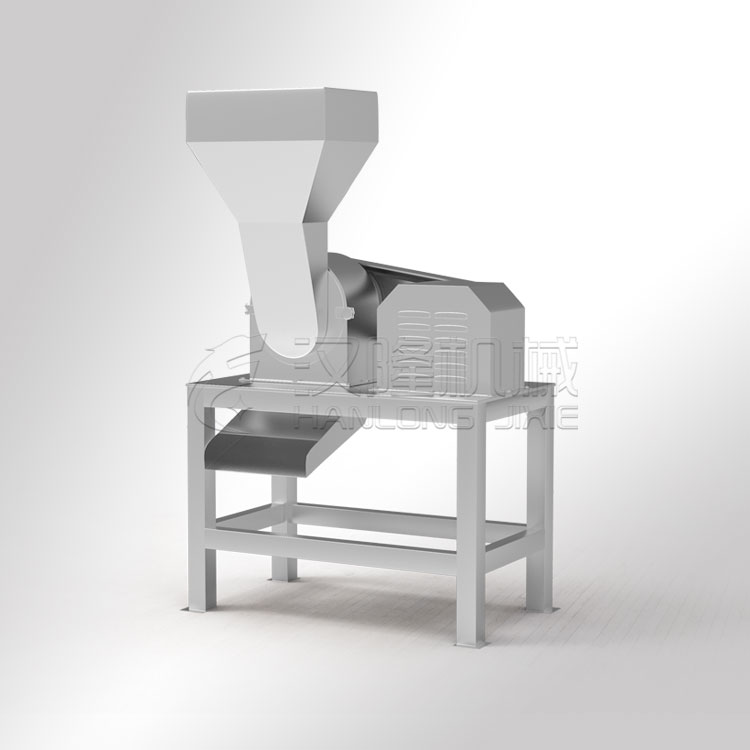

The industrial chili crushing machine is composed of a frame, a transmission cover, a bearing seat, a body, a feed hopper, a stator, a rotor, a blade, a large side cover, a discharge hopper, a hinge, a motor cover and other components. It is suitable for crushing apples, pears, tomatoes, roots and other fruits and vegetables (except stone fruits). When working, the motor drives the spindle to rotate. The material lifted up from the previous process falls into the hopper. After the material enters the fuselage, the ribs on the rotor rotate the material at a high speed. Under the action of centrifugal force, the knife row on the stator crushes the material (knife row). It can be used on both sides). At this time, the general particle size of the material is about 4-8mm (it can be determined according to the tooth pitch of the knife row, the slot width of the stator and the speed), and the crushed material falls into the waist-shaped hole on the stator.feed mouth。 Material mouth.