|

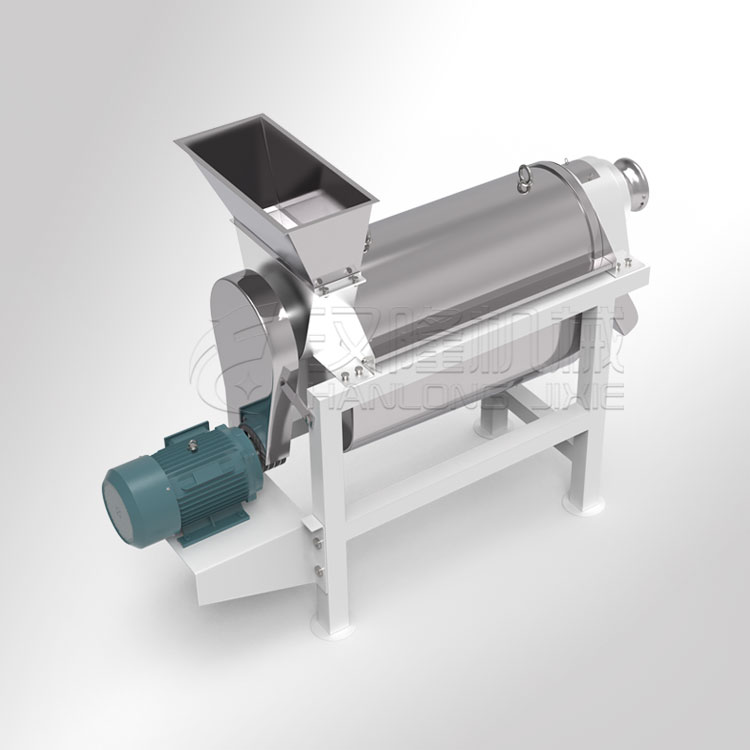

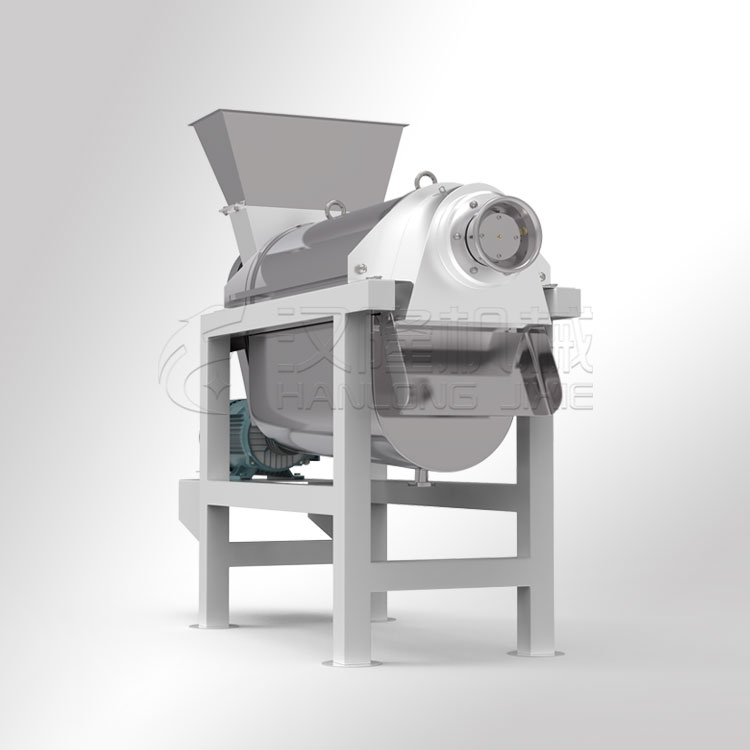

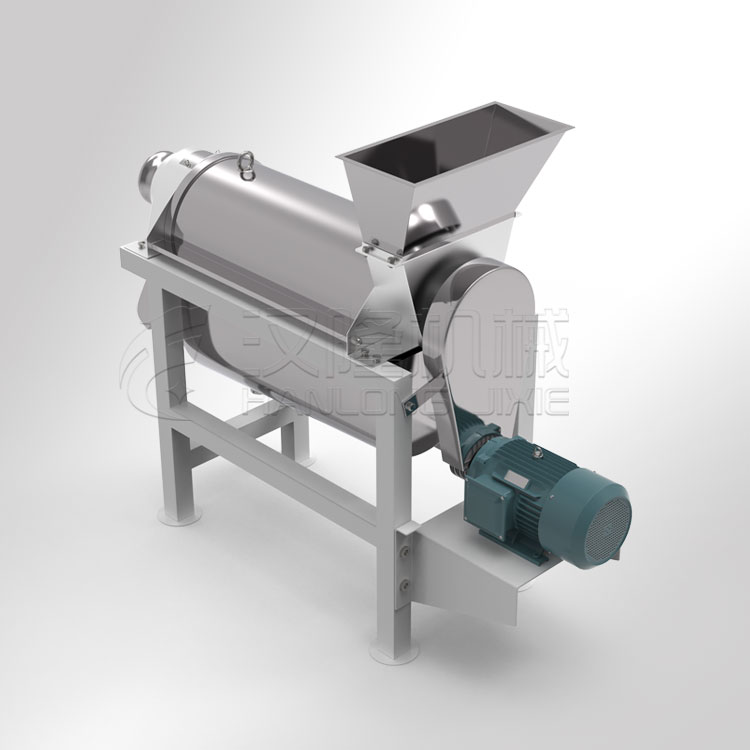

Model

|

Production capacityt/h

|

Matching power kw

|

Dimensions mm

|

||||

|

LZ-0.5

|

0.1-0.5

|

1.1

|

940×320×820

|

||||

|

LZ-1.5

|

0.5-1.5

|

4

|

1580×440×1320

|

||||

|

LZ-2.5

|

1.5-2.5

|

15

|

2020×640×1560

|

The coconut pulp juicer working principle is that the crushed pulp, juice and skin enter the screw juicer through the feeding hopper. Since the bottom diameter of the screw gradually increases along the direction of the slag outlet, the screw pitch gradually decreases. Shrinkage, resulting in the pressing of the material. The rotation direction of the screw spindle is counterclockwise when viewed from the feed hopper to the slag trough. The raw material is added into the feeding hopper and is pressed under the advancement of the screw. The squeezed juice flows into the juice container at the bottom through the filter screen, and the waste material is discharged through the annular gap formed between the screw and the conical part of the pressure regulation. The movement of the pressure regulating head along the axial direction can adjust the size of the gap. Turn the handwheel bearing seat handwheel by hand to change the size of the gap between the pressure regulating head and the spiral cone surface, that is, to adjust the resistance of the slag discharge to change the slag yield, but if the gap is too small, under strong extrusion , part of the slag particles will be squeezed out through the filter together with the juice. Although the juice output increases, the quality of the juice is relatively reduced, and the size of the gap should be determined by the user's specific process requirements. So as to achieve the purpose of automatic separation of juice and slag