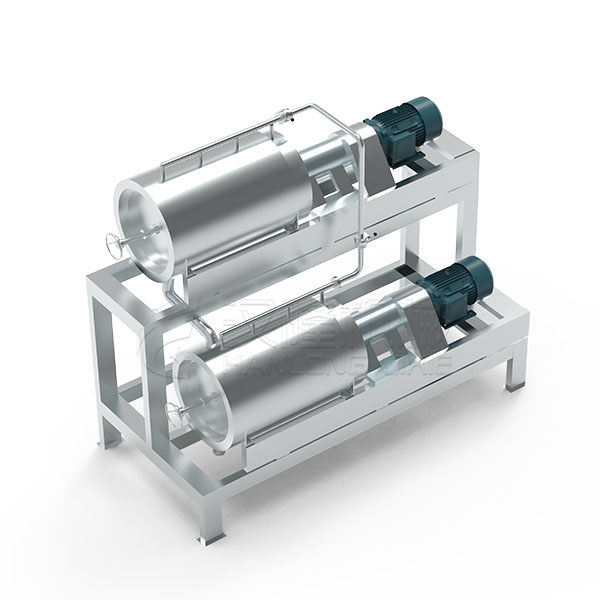

| Name | Technical indexes | ||||

| Production capacity | 10t/h | ||||

| Matched power | 30kw | ||||

| Conveyor speed | 970r/min | ||||

| Overall dimensions | 1980×1200×2050mm |

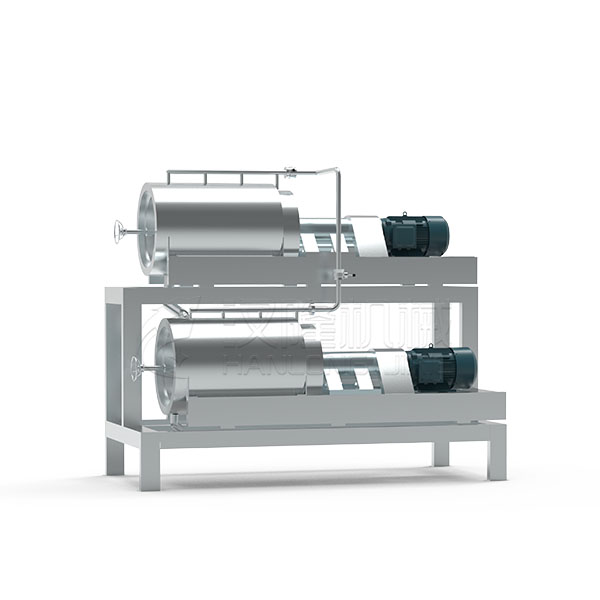

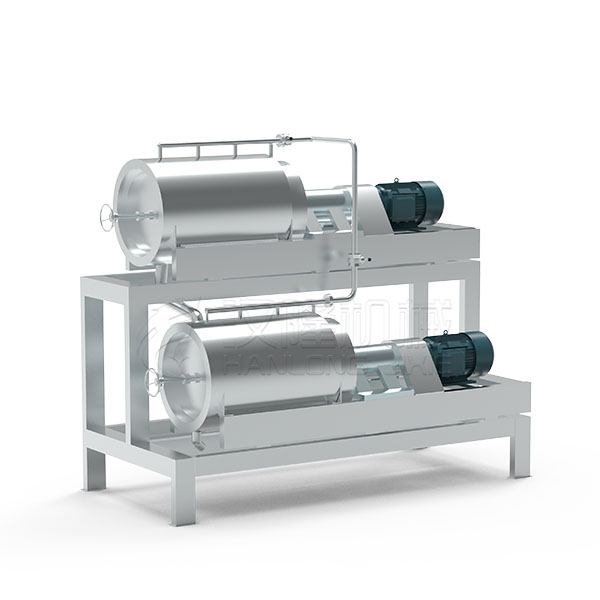

The working principle of industrial pulping machine: When working, the main shaft is driven by the transmission motor to rotate. When the crushed fruit is fed into a beater feed port by the feeding pump, the material enters the buffer chamber and then diffuses into the working cavity. Under the rotating action of the blade, the material moves along the cylinder to the outlet end, and the moving trajectory is in a spiral shape. Slurry) is sent from the screen hole through a pulping hopper to a second beating feed port, and the material is refined by the second beating. The skin and seeds are discharged from each slag hopper to achieve the purpose of automatic separation. At the same time, there is a dilution port on the drum of the beater, through which the material can be diluted. It can be seen from the schematic diagram of the structure that the machine is equipped with two stages of beating. The principle of the second stage of beating is the same as that of the first stage of beating.