|

Model

|

Production capacityt/h

|

Matched power kw

|

Overall dimension mm

|

||||

|

MDJ1-2.5

|

1-2.5

|

4

|

1450×820×1580

|

||||

|

MDJ2-4

|

2-4

|

7.5

|

1510×1370×1700

|

||||

|

MDJ2-7.5

|

4-7.5

|

18.5

|

1930×1540×1950

|

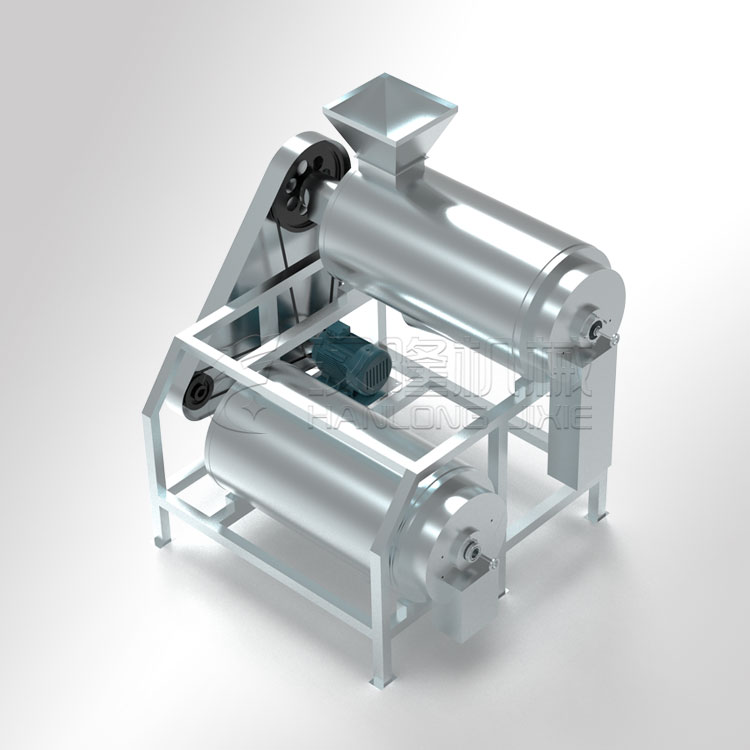

Pitting & pulping machine for fruits: The motor is driven by the belt to make the rotor part installed on the spline shaft rotate at a high speed, the fruit enters the machine from the feeding port, and the feeding paddle conveys the material to the beating rod. Under the action of the beating rod, the Material is smashed. Due to the existence of centrifugal force, the juice and flesh in the material (which have become pulpy) enter the next beating through the screen holes on the screen (the screen holes are determined according to the size of the fruit core), and the core is discharged from the slag pulp blade to the The slag outlet can realize automatic separation of pulp and slag.

The machine has two models: single-pass and double-pass. When used for beating stone fruit (such as mango), if a single-pass pitting beater is used, the flesh flows from the discharge hopper into the buffer tank, and the core is discharged from the slag. . De-nucleating double-pass beating machine, first-pass de-nucleating, second-pass beating realizes automatic separation of fruit core, peel and slag. It is recommended that users prefer to use the de-nuclear double-pass beater. The beating principle refers to the DJ type beating machine.