| Name | Technical indexes | ||||

| Cutter diameter |

336mm |

||||

| Knife tooth | 160个 |

||||

| Rotating speed |

43r/min |

||||

| Power | 1.5kw |

||||

| Dimensions | 1230×820×1050mm |

This machine is suitable for peeling coconuts after debrowning. The structure is simple, the operation is convenient, and the efficiency is high.

I. Overview

Coconut sheller is suitable for the shelling of coconuts. The machine has the characteristics of simple structure, convenient operation and high efficiency.

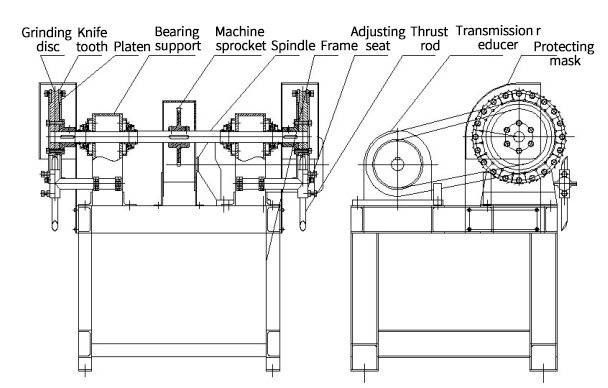

Second, the main structure diagram

Three, composition structure and working principle

The machine is mainly composed of frame, transmission reducer, sprocket, main shaft, cutter teeth, bearing seat and other important components.

Its main working principle: When working, the main shaft is driven by the transmission reducer so that the grinding disc rotates under the drive of the transmission sprocket. The top is equipped with knife teeth. When the coconut is placed between the grinding disc and the thrust rod, the coconut will be manually turned over, so that the coconut shell is peeled off under the combined action of the knife teeth and the thrust rod, so as to achieve the effect of shelling.

Four. Operation and precautions

1. The machine must be installed horizontally and fixed with anchor screws.

2. Tighten the bolts on the whole machine and check whether all the screws in the shaft are loose.

3. Turn on the power supply of the transmission reducer and confirm that the machine rotation direction is consistent with the direction indicator.

4. Test run for 5 minutes. After confirming that everything is normal, the machine can work.

5. If you find that the shelling effect is not satisfactory during work, you can adjust the distance between the thrust rod and the cutter teeth to make All the coconut shells are peeled off.

6. Regularly check the blade, and if it is worn, re-grind or replace the blade before use.

7. When stopping, just cut off the power of the motor.

8. Add lubricant to each part regularly.

9. Regularly check whether the reducer is overloaded and heated, and whether the bearing parts are refueled. If faults are found, they should be dealt with in time.