|

|

|

Model |

Production capacityt/h |

Matching power kw |

Dimensions mm |

|

|

|

|

|

CPJ-2 |

2 |

4 |

1050×750×1700 |

|

|

|

|

|

CPJ-5 |

5 |

7.5 |

1500×900×1800 |

|

|

|

|

|

CPJ-10 |

10 |

11 |

1500×1050×2000 |

|

|

|

|

|

CPJ-20 |

20 |

22 |

1800×980×2320 |

|

|

|

|

|

CPJ-30 |

30 |

30 |

1800×1100×2200 |

|

|

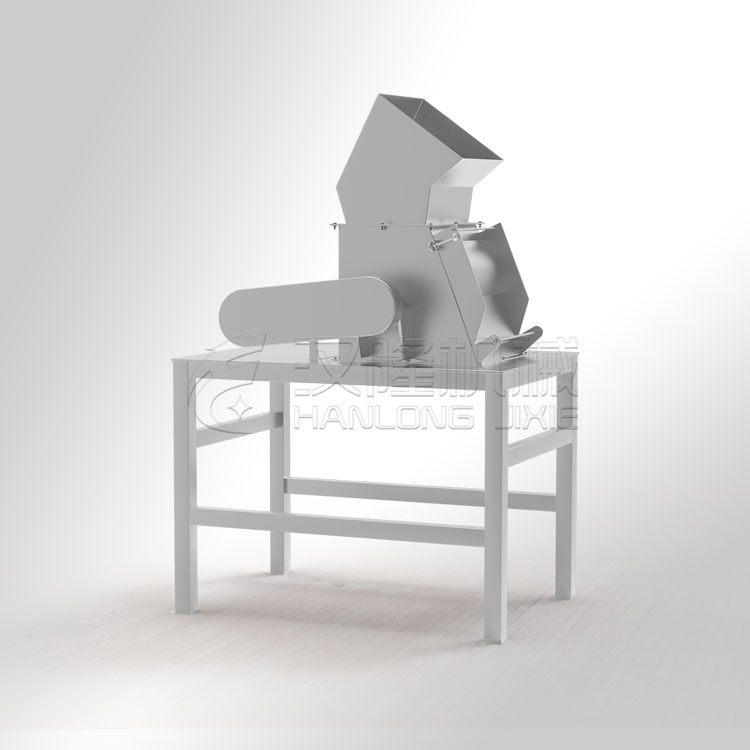

This equipment uses high-speed rotating blades to crush materials. The machine has the characteristics of simple structure, energy saving and high efficiency, and large production capacity. It is suitable for crushing all kinds of fruits and vegetables.

I. Overview

CPJ type hammer type crushing machine is a fruit and vegetable crushing machine with the current international advanced level designed by our company with the introduction of foreign advanced technology. Novel and compact, energy-saving, high-efficiency, large production capacity, wide application range and other advantages.

2, Structural features and working principle

The machine is composed of frame, body, door cover, feed hopper, flying knife, discharge hopper, drive motor and other components. When working, the motor drives the spindle to rotate. The material lifted up from the previous process falls into the hopper. After the material enters the fuselage, the flying knife on the main shaft rotates at a high speed, so that the material is broken, and the broken material falls into the waist-shaped hole on the screen. To the discharge port.

3, Installation, operation and maintenance

1. The machine must be installed horizontally and fixed with anchor screws.

2. Tighten all bolts on the whole machine. Clean the inside and outside of the whole machine to keep it clean.

3. Turn on the power supply of the drive motor and confirm that the direction of rotation of the machine is consistent with the direction indicator.

4. Test run for 5 minutes. After confirming that the machine is normal, you can feed normally.

5. The feed must be even, and hard foreign objects are strictly prohibited from entering the hopper to avoid damage to the screen.

6. When the machine stops, just cut off the power of the motor directly.

7. After each shift, open the door cover, take out the screen, and wash the screen with water and a brush.

8. Regularly check whether the motor is overloaded and heats up, and whether the bearing part is oiled.