|

Model

|

Production capacityt/h

|

Matched power kw

|

Overall dimension mm

|

||||

|

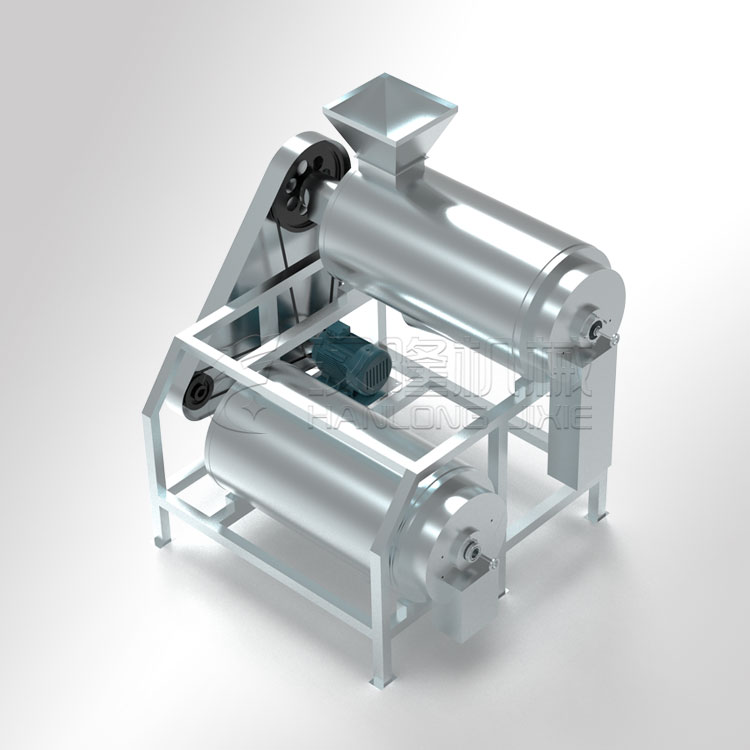

MDJ1-2.5

|

1-2.5

|

4

|

1450×820×1580

|

||||

|

MDJ2-4

|

2-4

|

7.5

|

1510×1370×1700

|

||||

|

MDJ2-7.5

|

4-7.5

|

18.5

|

1930×1540×1950

|

Lage size pulping machine working principle: The motor is driven by a belt, so that it is installed on the spline shaft

The scraper rotates at a high speed, the bayberry enters the machine through the feeding port, and the feeding slurry evenly discharges the material to the scraper and the screen. Due to the rotating action of the scraper and the existence of the lead angle, the material moves along the cylinder to the outlet end, and the moving trajectory is spiral, and the material is affected by centrifugal force during the movement between the scraper and the screen cylinder. Grind, the juice and meat (in the form of pulp) are sent to the next process through the sieve hole, and the skin and seeds are discharged from the slag hopper to achieve the purpose of automatic separation. As long as the screens of different specifications are changed and the lead angle of the scraper is adjusted, different beating speeds can be changed to obtain satisfactory results.