|

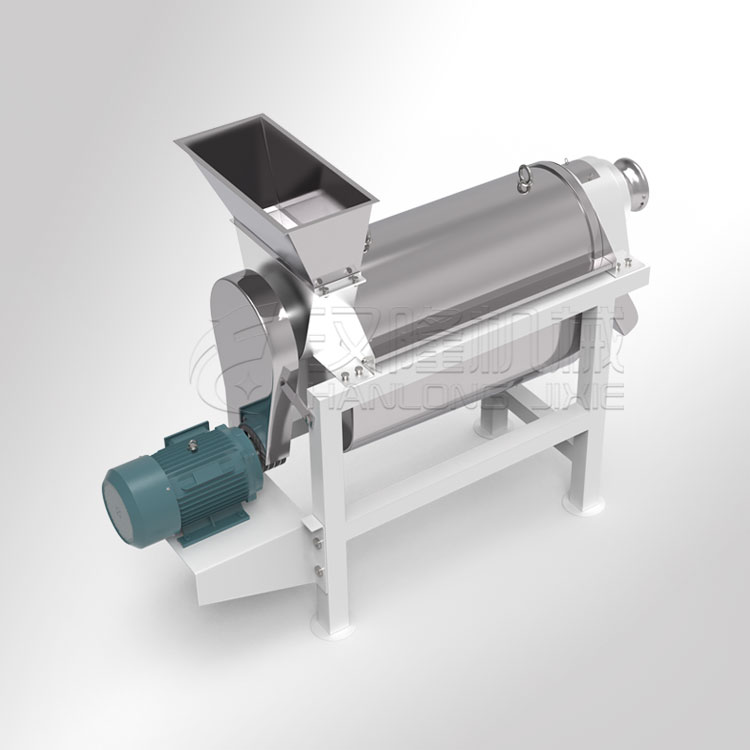

Model

|

Production capacityt/h

|

Matching power kw

|

Dimensions mm

|

||||

|

LZ-0.5

|

0.1-0.5

|

1.1

|

940×320×820

|

||||

|

LZ-1.5

|

0.5-1.5

|

4

|

1580×440×1320

|

||||

|

LZ-2.5

|

1.5-2.5

|

15

|

2020×640×1560

|

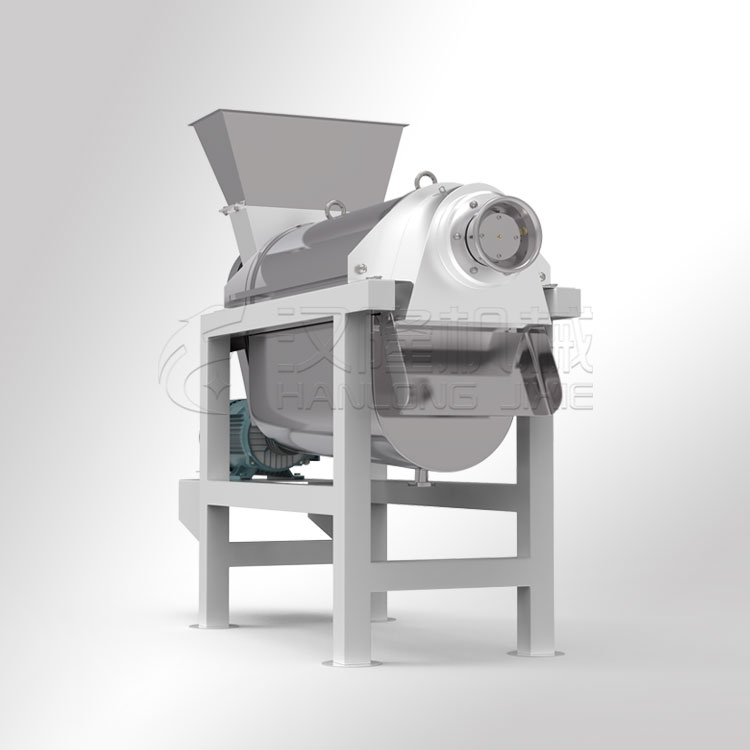

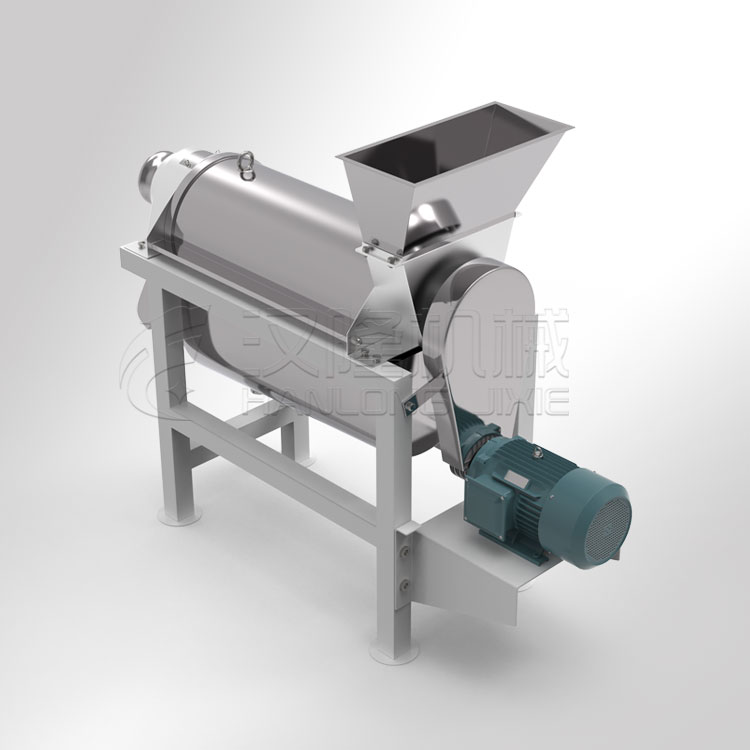

The working process of the screw juicer

The screw shaft rotates clockwise along the direction of the slag outlet, the bottom diameter gradually increases and the pitch gradually shrinks. When the material is pushed by the screw shaft, the screw cavity gradually shrinks, thus forming the pressing of the material.

The fruits and vegetables are added into the hopper. Under the advancement and extrusion of the screw shaft, the squeezed juice flows into the juice container at the bottom through the filter screen, and the slag is formed by the ring formed between the screw shaft and the conical part of the pressure regulating head. The size of the gap can be adjusted by the pressure regulating head to adjust the resistance of the slag discharge, and the slag discharge rate can be changed. The size of the gap of the pressure regulating head should be determined according to the technological requirements of the processed fruits and vegetables.

When the screw juicer is working, the screened material enters the hopper from the conveyor, and flows into the pressing chamber under the action of gravity after the flow is adjusted by the regulating plate. Due to the rotation of the pressing screw, the material is moved axially forward in the pressing chamber by the action of the screw. As the rhizomes of the snail squeezer become larger and the pitch of the screw becomes smaller, the volume of the squeezing chamber becomes smaller. Therefore, the extrusion force on the material is increasing. On the other hand, due to the increased friction, the temperature of the material is getting higher and higher, prompting the juice to flow out of the material. The separated juice is discharged from the gap between the pressing bars, the slag cake is extruded from the slag discharge ring, and the slag is discharged from the slag outlet.

The gap between the pressing screw and the tap ring is controlled by the adjusting hand wheel 9 . It adjusts the slag thickness and slag volume according to the predetermined process requirements. When the handwheel is reversed, the slag is thin, and when the handwheel is turned forward, the slag is thick.