| Name | Technical indicators | ||||

| Production capacity |

5t/h |

||||

| Rough crushing speed | 70r/min |

||||

| Fine crushing speed |

70r/min |

||||

| Screening speed | 1.6-8r/min |

||||

| Mixing conveying speed | 200-100r/min | ||||

| Equipped with power | 6kw | ||||

| Dimensions | 3000× 1060×2510mm |

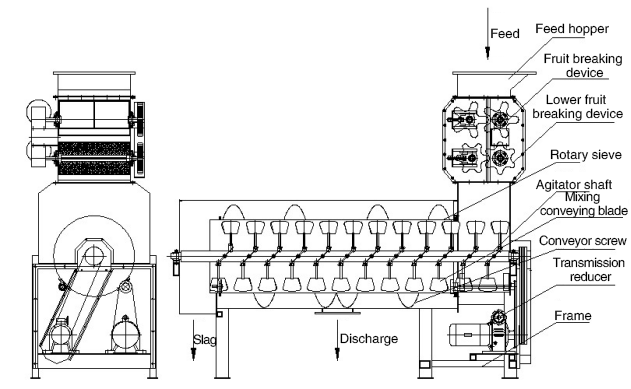

The pomegranate enters the upper crushing device from the feed hopper. The upper crushing device squeezes the pomegranate open, and the lower crushing device squeezes the pomegranate again. The pomegranate after the two-stage squeezing has basically separated the skin and seeds, and falls into the separation device. The seeds fall from the sieve hole, the skin is discharged from the tail, and the seeds and juice are pumped to the next process with a separate screw pump.

1. Overview

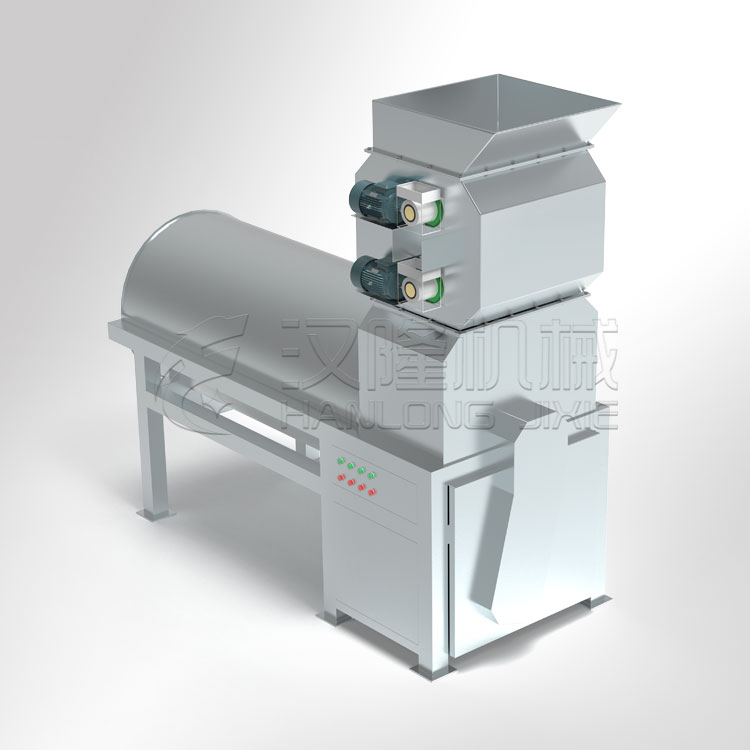

Pomegranate peeling and separating machine is a pomegranate peeling and separating machine designed and manufactured by our company with the introduction of foreign advanced technology. It has the characteristics of novel structure, high efficiency, energy saving and high production efficiency. This machine can be used for breaking and separating hard fruits such as pomegranate and passion fruit.

2, Structural features and working principle

The pomegranate peeling and separating machine is mainly composed of the feed hopper, the upper fruit breaking device, the lower fruit breaking device, the rotating screen, the mixing shaft, the conveying screw, and the machine Frame and other components. This machine is made of stainless steel except for the transmission part, and the stirring shaft is steplessly adjustable.

Working principle: The pomegranate enters the upper fruit breaking device from the feeding hopper, and is pressed open and coarsely broken under the action of the opposing pressure between the two pressure rollers The fruit then enters the lower fruit breaking device, and the lower fruit breaking device squeezes the pomegranate again. At this time, the pomegranate that has undergone two-stage squeezing has basically separated its shell and flesh and falls into the separating device. The upper and lower fruit breaking rollers are of elastic structure, and the gap is adjustable. Under the action of the mixing and conveying blades on the mixing shaft, the broken pomegranate pulp drops from the sieve holes and is sent to the discharge port under the action of the spiral outside the rotating sieve, while the pomegranate skins are discharged from the tail under the action of the mixing and conveying blades. . The pomegranate pulp and juice from this machine can be transported to the next process with a screw pump.

3, Installation, adjustment, use, operation

1. The machine must be installed horizontally and fixed with anchor screws.

2. Tighten all bolts on the whole machine, clean the inside and outside of the whole machine to keep it clean.

3. The bearings and reducer parts are required to be well lubricated, and lubricating oil with specified marks is added regularly.

4. After the above conditions are confirmed to be correct, the test machine can be switched on.

5. Turn on the power of each transmission motor and confirm that the rotation direction of each transmission device is consistent with the direction indicator.

6. Test run several times, each time for 5 minutes, cut off the power supply, re-check according to the above requirements, and only after confirming that it is correct, can the test run with materials .

7. Feed the material into the hopper and check the slag outlet and the slag outlet: if the slag contains more pulp and is separated from the slag, the speed of the mixer shaft reducer can be adjusted when the machine is running (on the reducer) Adjust the handwheel) or adjust the angle of the mixing and conveying blades after the shutdown to achieve a good separation effect; if there is more pulp in the slag, and it is not separated from the slag, the better can be achieved by replacing the spring with a larger compression force. Crushing effect; if the pulp discharge is slow, it can be controlled by adjusting the speed of the rotating sieve. (Adjustment method: when the machine is running, it is realized by the adjustment handwheel on the reducer of the transmission rotating screen)

8. The machine can only be continuously fed and produced normally after the trial feeding operation.

9. Stones, screws, and tools are strictly prohibited from falling into the machine.

10. Frequently check whether the motor is overloaded and heats up. If any defects are found, please contact the maintenance personnel for repair.

11. After shutting down, open the cover of the machine to clean out the remaining pulp and peel, and keep the whole machine clean.

12. Check whether the transmission belt is aging or cracked. If found, replace it in time.

13. Check whether the drive belt is loose or too tight, usually turning the belt 90o with your fingers. If it is too loose or too tight, adjust the locking bolt at the bottom of the motor.

14. Always keep the inside and outside of the whole machine clean.

15. The normal use temperature of the bearing is less than 75oC