|

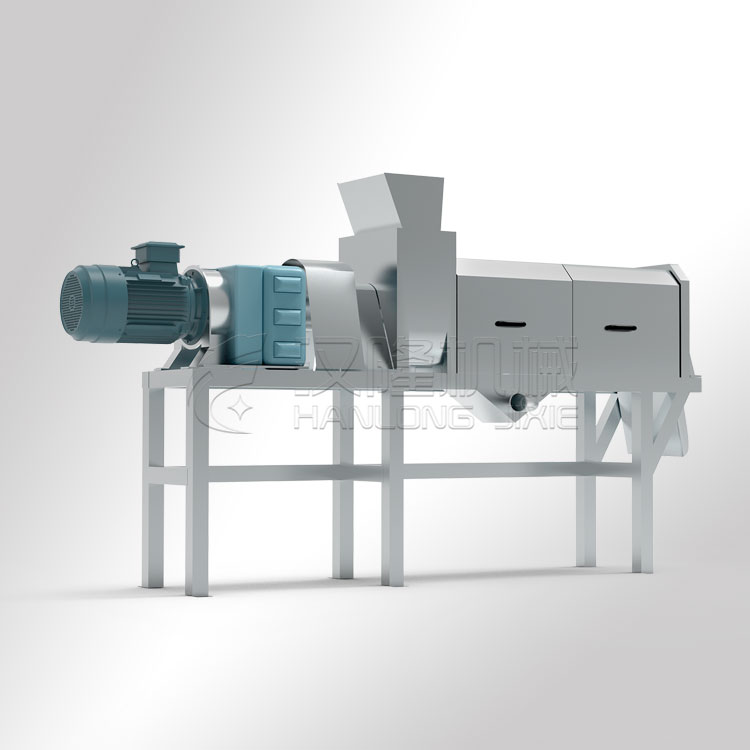

model

|

production capacity t/h

|

matched power kw

|

boundary dimension mm

|

|

DLZ-0.5

|

0.3-0.8

|

4+2.2

|

2150×750×1650

|

|

DLZ-1.5

|

0.8-1.5

|

4+5.5

|

2270×750×1850

|

|

DLZ-2.5

|

1.5-2.5

|

15+7.5

|

2920×950×2445

|

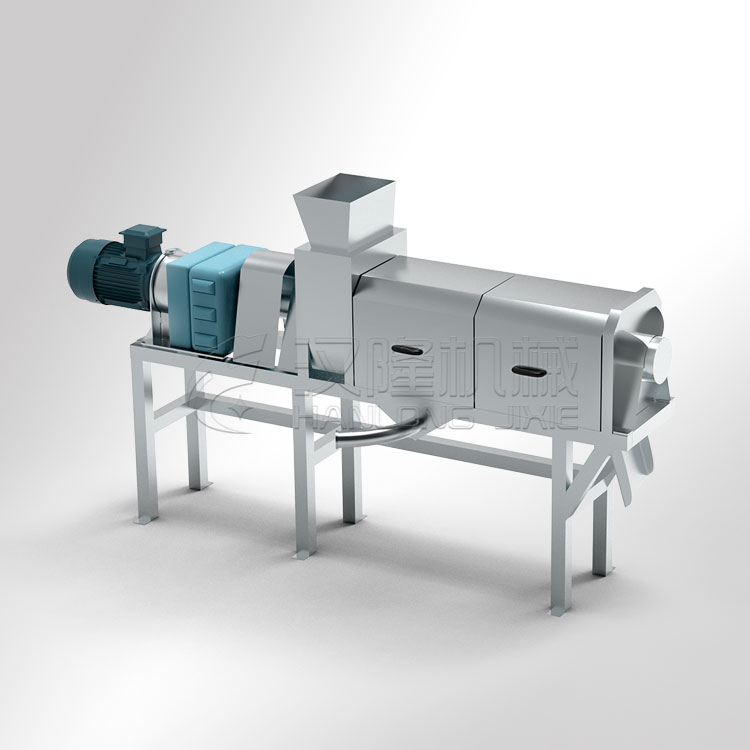

purple potato basic principle of single screw press filter mainly for reference in the double helix of filter press, my company on the basis of the simplified and improved, the type of equipment for material not fussy, can satisfy the solid-liquid separation process, the vast majority of material crushing ratio (4:1), high rate of juice is larger, higher than that of traditional spiral juicer run slow, will have to heat up in the process of crushing; Work is, the broken even after the material into the feed box, diameter by the pitch change at the end of the press screw axis rotation to push forward the material (pitch from large to small, bottom diameter changes from small to big), material by the extrusion pressure between the blade and blade, to squeeze the juice, finally the material being transported to discharge cone plate of institutions, discharge cone plate mechanism is provided by the rear of the cylindrical compression spring tension, The material is blocked in the spiral juice bin, because the subsequent material is continuously pressed forward, when the extrusion pressure of the material is greater than the spring behind the adjustment of the cone disc mechanism to provide elasticity, the slag will be discharged from the gap opened by the cone disc mechanism, the greater the elastic adjustment, the greater the extrusion pressure, the higher the rate of juice.