| Name | UHT-1 Type | UHT-2 Type | ||||

| Production capacity | 700-1000 | 1500-2000 | ||||

| Sterilization time s | ≈4 | ≈4 | ||||

| Sterilization temperature℃ | 115-135 | 115-135 | ||||

| Steam pressure Mpa | <0.78 | <0.78 | ||||

| Steam consumption kg/L | 0.15 | 0.15 | ||||

| Material outlet temperature ℃ | 4-65 | 4-65 | ||||

| Pump power kw | 1.5 | 2.2 (4.4) | ||||

| Holding time s | ≤45;≤65 | ≤45;≤65 |

This machine is suitable for high temperature and instantaneous sterilization of liquid materials such as milk, soy milk, fruit juice, etc. It has the characteristics of high efficiency, energy saving, simple operation and good sterilization effect.

1. Product model and name

UHT type ultra high temperature instant sterilizer

2. Purpose and scope of application

This equipment is suitable for instantaneous quenching of liquid foods such as fresh milk, fruit juice, beverages, popsicles and ice cream slurry, soy sauce, soy milk, condensed milk, alcohol, etc. Bacteria can also be used for the sterilization of fluid medicines, and the effect is very significant.

3. Main structure and working principle

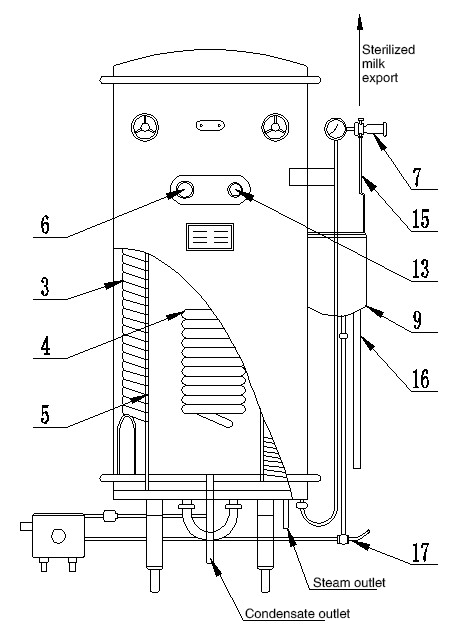

The structure of the ultra high temperature instant sterilizer is shown in Figure 1. A pressure vessel, a high temperature barrel (5), is installed in the main unit for filling Pressure steam. The main setting outside the barrel is a spiral double sleeve (3), which is used for the cold and heat exchange of incoming and outgoing materials; the main setting inside the barrel is a spiral single tube (4), which is used to receive heat indirectly.

Figure 2 depicts the sterilization process of the material. The material enters the outer flow channel of the double coil pipe (3) through the feed pump (2) and is preheated by the indirect heating of the hot material flowing out of the inner layer. When the material enters the high temperature set in the high temperature barrel (5) When the coil (4) is indirectly heated by the steam in the barrel, it is heated to the required sterilization temperature, and then the single coil outside the barrel is kept warm to kill the bacteria of the material. When returning to the double coil (3) ), the material enters the inner flow channel and is cooled by the outer cold material, so that the discharge temperature is significantly reduced (generally lower than 65°C). If it is necessary to increase or decrease the discharge temperature in the process, the angle type shut-off valve (12) can be activated to connect the heat source (steam) or cold source (water, or ice water, etc.) to the lower end of the double sleeve. Outer runner.

The throttle valve (7) can be adjusted. On the one hand, the material is maintained under a certain pressure and the boiling point temperature is increased to prevent Desalination; on the other hand, it is also used to adjust flow. The material will be discharged through the three-way cock (8) after the final product. The lower end of the cock is connected to the coil (15), and its outlet faces the storage tank (9). When necessary, the coil can be rotated to turn the overflow pipe (16). The upper end of the feed three-way cock (1) is connected with the storage tank (9), and the lower end is connected with the material source pipeline.

When the processing capacity needs to be improved, the “U” tube (17) can be removed to modify a centrifugal pump, the connection method is shown in Figure 3.

This machine is a hand-controlled sterilizer, and the sterilization temperature is adjusted by the angle cut-off valve (11) (see Figures 1 and 2). The discharge temperature can be changed by the angle shut-off valve (12). The steam pressure gauge (13), the sterilization temperature gauge (6) and the discharge temperature gauge (14) are all installed on the host.