|

model

|

production capacity t/h

|

matched power kw

|

boundary dimension mm

|

|

DLZ-0.5

|

0.3-0.8

|

4+2.2

|

2150×750×1650

|

|

DLZ-1.5

|

0.8-1.5

|

4+5.5

|

2270×750×1850

|

|

DLZ-2.5

|

1.5-2.5

|

15+7.5

|

2920×950×2445

|

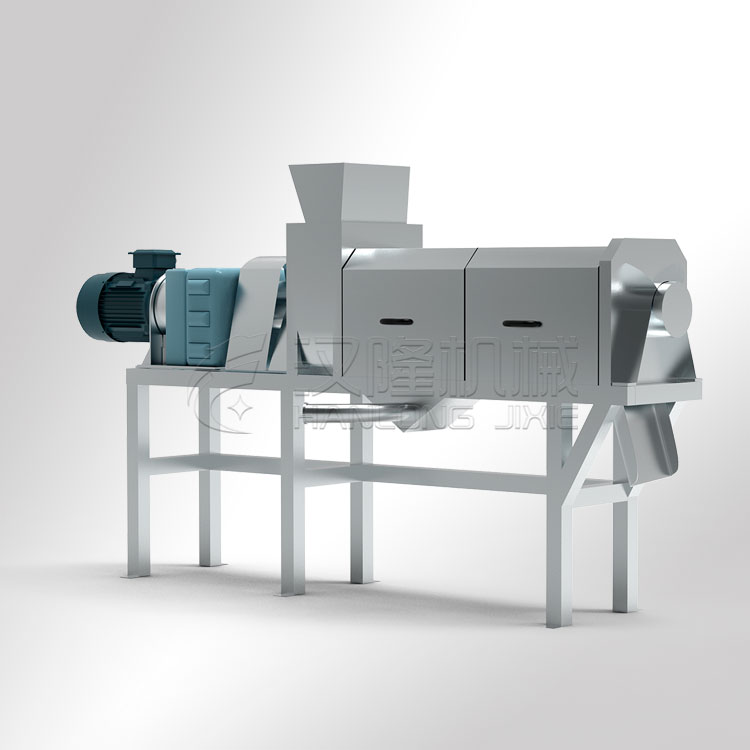

The equipment is mainly composed of a helical gear reducer, a coupling, a feeding box, a variable-pitch variable-diameter pressing screw, a detachable filter screen, a discharge adjustment cone-disc mechanism, a bearing seat, a frame, a juice outlet, and a slag hopper. (See attached picture for details); Except for the helical gear reducer and coupling, the equipment is all made of SUS304 stainless steel, and the overall appearance is polished and beautiful.

When working, the evenly crushed material is conveyed into the feed box, and the pressing screw shaft with variable pitch and bottom diameter rotates to push the material forward (the pitch changes from large to small, and the bottom diameter changes from small to large), and the material is affected by the blade. The squeezing force between the blade and the blade squeezes out the juice, and finally the material is transported to the discharge adjustment cone-disc mechanism. The discharge adjustment cone-disc mechanism is provided with elastic force by the rear cylindrical compression spring to block the material in the spiral juice extraction bin. , Since the subsequent materials are continuously squeezed and conveyed forward, when the extrusion force of the material is greater than the elastic force provided by the spring behind the adjusting cone-disc mechanism, the slag will be discharged from the gap opened by the cone-disc mechanism. The higher the pressure, the higher the juice yield.