|

Model

|

Production capacityt/h

|

Matching power kw

|

Dimensions mm

|

||||

|

LZ-0.5

|

0.1-0.5

|

1.1

|

940×320×820

|

||||

|

LZ-1.5

|

0.5-1.5

|

4

|

1580×440×1320

|

||||

|

LZ-2.5

|

1.5-2.5

|

15

|

2020×640×1560

|

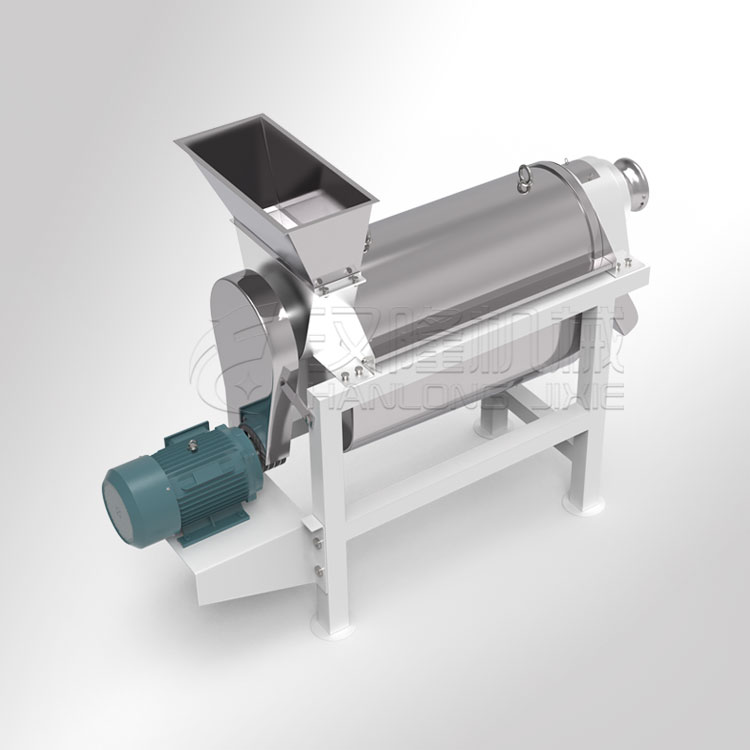

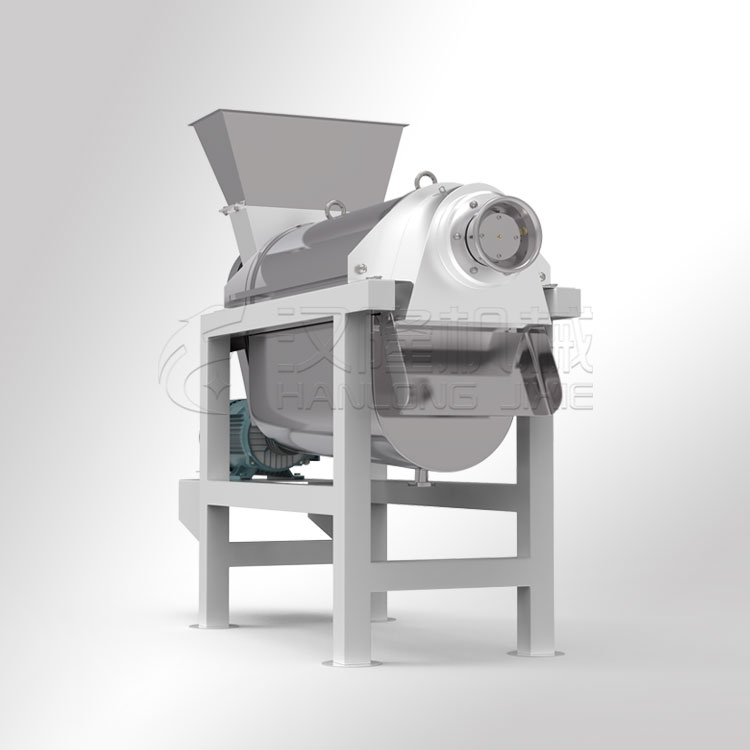

The composition and use characteristics of the screw juicer.

1. The screw juicer is composed of feed hopper, screw shaft, filter screen, juice container, rear support, slag discharge tank and other components.

2. The left end of the screw spindle is supported in the rolling bearing seat, and the right end is supported in the hand wheel bearing seat. The motor drives the screw shaft to run through a pair of pulleys.

3. The screw shaft of the screw juicer rotates clockwise along the direction of the slag outlet, and the bottom diameter gradually increases and the pitch gradually decreases. When the material is pushed by the screw shaft, the screw cavity gradually shrinks, thereby forming a squeeze on the material. .

The fruits and vegetables are added into the hopper. Under the advancement and extrusion of the screw shaft, the squeezed juice flows into the juice container at the bottom through the filter screen, and the slag is formed by the ring formed between the screw shaft and the conical part of the pressure regulating head. The size of the gap can be adjusted by the pressure regulating head to adjust the resistance of the slag discharge, and the slag discharge rate can be changed. The size of the gap of the pressure regulating head should be determined according to the technological requirements of the processed fruits and vegetables.

principle

The screw shaft rotates clockwise along the direction of the slag outlet, the bottom diameter gradually increases and the pitch gradually shrinks. When the material is pushed by the screw shaft, the screw cavity gradually shrinks, thus forming the pressing of the material.

The fruits and vegetables are added into the hopper. Under the advancement and extrusion of the screw shaft, the squeezed juice flows into the juice container at the bottom through the filter screen, and the slag is formed by the ring formed between the screw shaft and the conical part of the pressure regulating head. The size of the gap can be adjusted by the pressure regulating head to adjust the resistance of the slag discharge, and the slag discharge rate can be changed. The size of the gap of the pressure regulating head should be determined according to the technological requirements of the processed fruits and vegetables.

Want to know more about customer service

Article link: Agricultural Machinery Network https://www.nongjx.com/tech_news/detail/43561.html

与此原文有关的更多信息要查看其他翻译信息,您必须输入相应原文