|

model

|

production capacity t/h

|

matched power kw

|

boundary dimension mm

|

|

DLZ-0.5

|

0.3-0.8

|

4+2.2

|

2150×750×1650

|

|

DLZ-1.5

|

0.8-1.5

|

4+5.5

|

2270×750×1850

|

|

DLZ-2.5

|

1.5-2.5

|

15+7.5

|

2920×950×2445

|

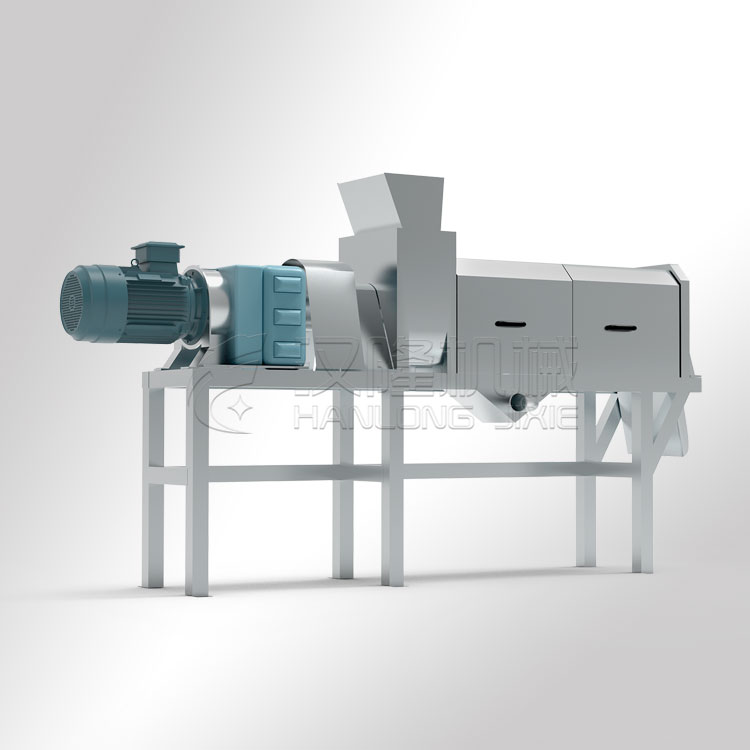

Basic principle of single screw press filter mainly for reference in the double helix of filter press, my company on the basis of the simplified and improved, the type of equipment for material not fussy, can satisfy the solid-liquid separation process, the vast majority of material crushing ratio (4:1), high rate of juice is larger, higher than that of traditional spiral juicer run slow, will have to heat up in the process of crushing; Work is, the broken even after the material into the feed box, diameter by the pitch change at the end of the press screw axis rotation to push forward the material (pitch from large to small, bottom diameter changes from small to big), material by the extrusion pressure between the blade and blade, to squeeze the juice, finally the material being transported to discharge cone plate of institutions, discharge cone plate mechanism is provided by the rear of the cylindrical compression spring tension, The material is blocked in the spiral juice bin, because the subsequent material is continuously pressed forward, when the extrusion pressure of the material is greater than the spring behind the adjustment of the cone disc mechanism to provide elasticity, the slag will be discharged from the gap opened by the cone disc mechanism, the greater the elastic adjustment, the greater the extrusion pressure, the higher the rate of juice.

The dehydrator is mainly composed of screw, cylindrical cage shell and cone. The flexible coupling connects the screw shaft with the output shaft of the reducer.

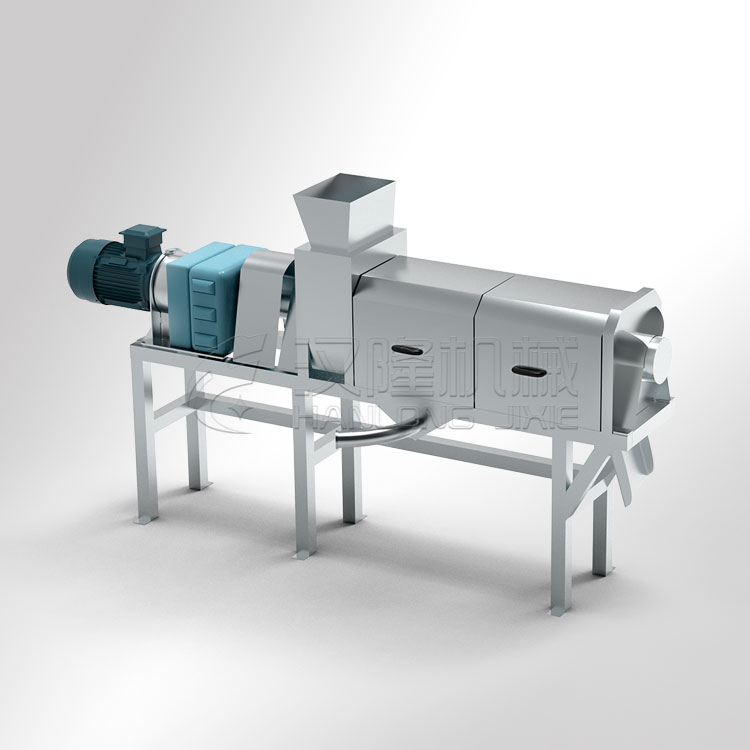

1. The screw

It consists of a pitch thread and a shaft ring set alternately on the screw shaft. Each thread and shaft ring are fixed on the screw shaft with keys respectively. Thread except the first section (feeding area) for three equal distance continuous thread, the rest of the sections are single turn open, the pitch of each section is not the same, from the low pressure side to the high pressure side gradually reduced, the diameter of the hub is gradually increased to increase the pressure, so as to extricate rubber moisture.

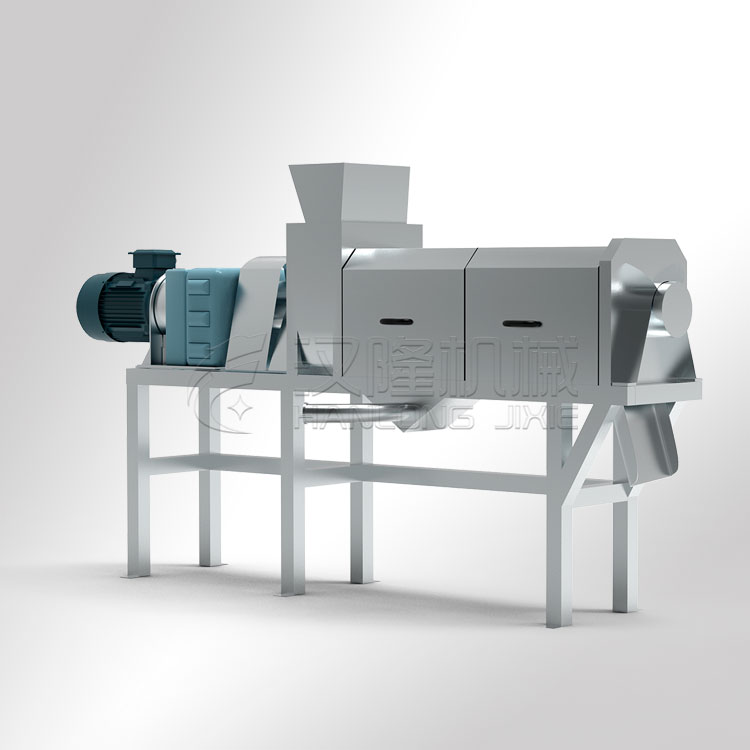

2. Cylindrical shell

The labyrinth is composed of panels made of cage strips fixed to the skeleton. The grate is divided into eight pieces, each of different length. The cylinder has an 18-inch diameter and is bolted in two halves on the vertical center line to facilitate removal for cleaning and maintenance. The cage strips that make up the grate are separated by spring sheets to form longitudinal slits to allow water to flow out. A scraper is arranged on the skeleton on both sides of the cylinder, corresponding to the position of the shaft ring on the screw. Its role is to prevent the rubber from rotating with the screw, forcing the rubber to change the direction and position of propulsion, and make it form loose and porous shape, so as to facilitate drying. Outside the cylinder is provided with four jackets for heating or cooling, which can control the temperature in the machine according to the process requirements. In the production of styrene butadiene rubber, it is only used when steam is used to preheat the body before starting up.

3. The cone

This is a conical cylinder located in the discharge area, which can be moved back and forth to match the ring fixed on the screw shaft. Cone forward and backward movement is driven by a speed regulating motor through a gear consisting of four jacks at the same time there is also a manual adjustment mechanism. By moving the cone back and forth to increase or decrease the area of the outlet sharp hole, in order to change the pressure in the machine, so as to adjust the rubber dehydration rate. After the rubber is extruded from the sharp hole in the cone, it is cut into small pieces by a tool mounted on the screw shaft. Because the rubber in the machine by the machine shear and compression temperature rise, so through the sharp hole in the cone rubber water flash, so that the rubber is loose porous.